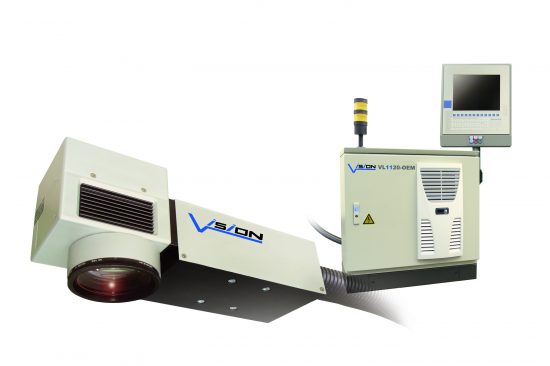

The compact, flexible OEM module from Vision Lasertechnik is ideal for production line integration and for the development of customised marking systems.

The module is available with high-performance fibre lasers (10 to 50 watts) in line with your requirements. Air cooling, low running costs and excellent beam quality are the key benefits of this laser source.

The OEM modules can also be fitted with CO lasers (20 to 100 W) for marking organic and inorganic materials.

Our customers in the industrial automation sector look for three things above all:

reliability, performance and integration support.

Success in this market segment demands courage and innovation. In other words, it is not low components prices that matter, but maximum performance with maximum reliability.

Quality is our top priority in the choice of enclosures, electrical components and sub-modules. The parts and modules that we use must still be available in many years’ time, and perform consistently and reliably. This is particularly important for the industrial computers used, and for key sensor system components.

Our special software together with our digital IO cards allows you to control not just the marking process itself but also all related processes.

Part feed and discharge processes, and adjusting or changing part position with image recognition and sensors are just a few examples.

High-performance computers operating with intelligent sub-modules enable marking on the fly at high line speeds.

The OEM module can be connected to existing systems over a wide range of available interfaces, or separately from the control systems in place using optional sensors.

| Technical Data | IPG Fiber 20W |

|---|---|

| laser head | diode-pumped Ytterbium Fiberlaser, with integrated pilot-beam (red) |

| cw-Betrieb | no |

| Wellenlänge | 1064 nm |

| Leistung | 20W |

| M2-Richtwert | 1,5 |

| Q-switch-Betrieb | |

| Pulsenergie | 1 mJ at 20 kHz |

| Peak to Peak Stabilität | 5% |

| Pulsdauer | 100 ns |

| max. Pulsfrequenz | 80 kHz |

| Abmessung Lasermodul in mm | 215 x 95 x 286 mm |

| Umgebungstemperatur | 0°...35° |

| Dimensions |

| Technical Data | IPG Fiber 30 W |

|---|---|

| laser head | diode-pumped Ytterbium Fiberlaser, with integrated pilot-beam (red) |

| cw-Betrieb | no |

| Wellenlänge | 1064 nm |

| Leistung | 30 W |

| M2-Richtwert | 1,5 |

| Q-switch-Betrieb | |

| Pulsenergie | 1mJ at 30 kHz |

| Peak to Peak Stabilität | 5% |

| Pulsdauer | 100 ns |

| max. Pulsfrequenz | 80 kHz |

| Abmessung Lasermodul in mm | 201 x 95 x 286 |

| Umgebungstemperatur | 0...35°C |

| Dimensions |

| Technical Data | IPG Faser 50W |

|---|---|

| Laserkopf | diodengepumpter Ytterbium Faserlaser, mit integriertem Pilotlaser (rot) |

| cw-Betrieb | |

| Wellenlänge | 1064 nm |

| Leistung | 50 W |

| M2-Richtwert | 1,5 |

| Q-switch-Betrieb | |

| Pulsenergie | 1 mJ bei 50 kHz |

| Peak to Peak Stabilität | 5% |

| Pulsdauer | 120 ns |

| max. Pulsfrequenz | 100 kHz |

| Abmessung Lasermodul in mm | 201 x 95 x 286 |

| Umgebungstemperatur | 0...35°C |

| Dimensions |

| Technical Data | SPI Faser 20 W |

|---|---|

| Laserkopf | diodengepumpter Ytterbium Faserlaser |

| cw-Betrieb | ja |

| Wellenlänge | 1064 nm |

| Leistung | 20 W |

| M2-Richtwert | <1,6 |

| Q-switch-Betrieb | |

| Pulsenergie | 1 mJ |

| Peak to Peak Stabilität | 3% |

| Pulsdauer | 3-500 ns |

| max. Pulsfrequenz | 1000 kHz |

| Abmessung Lasermodul in mm | 347,5 x 201 x 95 |

| Umgebungstemperatur | 0...35°C |

| Dimensions |

| Technical Data | SPI Faser 50 W |

|---|---|

| Laserkopf | diodengepumpter Ytterbium Faserlaser |

| cw-Betrieb | ja |

| Wellenlänge | 1064 nm |

| Leistung | 50 W |

| M2-Richtwert | <1,6 |

| Q-switch-Betrieb | |

| Pulsenergie | 1 mJ |

| Peak to Peak Stabilität | 3% |

| Pulsdauer | 7-500 ns |

| max. Pulsfrequenz | 1000 kHz |

| Abmessung Lasermodul in mm | 347,5 x 201 x 95 |

| Umgebungstemperatur | 0...35°C |

| Dimensions |

| Technical Data | SPI Faser 70 W |

|---|---|

| Laserkopf | diodengepumpter Ytterbium Faserlaser |

| cw-Betrieb | ja |

| Wellenlänge | 1064 nm |

| Leistung | 70 W |

| M2-Richtwert | <1,6 |

| Q-switch-Betrieb | |

| Pulsenergie | 1 mJ |

| Peak to Peak Stabilität | 3% |

| Pulsdauer | 10-500 ns |

| max. Pulsfrequenz | 1000 kHz |

| Abmessung Lasermodul in mm | 377,2 x 248 x 95 |

| Umgebungstemperatur | 0...35°C |

| Dimensions |

Labelling components with a data matrix or a barcode has become virtually indispensable in the industry today. Naturally, logos and plain text can also be lasered. As an option, the applied marking can be checked by reading it out and verifying it.

A camera system can optionally be integrated to recognise and select the location of the work pieces. We therefore provide perfect alignment and flawless handling even for bulk material.

In-Sight@ Vision systems • robust, industrial image processing systems with recording and processing rates at high speed • suitable for verifying, identifying and managing parts: • 1D/2D code recognition and verification • recognition of OCR font • Position and part recognition and inspection of parts • easy to operate and powerful software • extensive image processing libraries

• Connection to S7 automation systems in the manufacturing industry via PROFIBUS or PROFINET IO • freely definable communication interfaces for a flexible connection to the whole system • for a safe and high-performance transfer of marking contents and process parameters • for the part handling and sequence control as well as confirmation of status information, error codes and process results • hardware connection via SIEMENS PC interface cards CP5611 and CP1616

Here you can find extensive information on the various marking processes