In our company, Vision Lasertechnik, we make qualified welding engineers available to you to fulfil your welding needs.

Alongside advice about technical feasibility and the welding of small and large batches, we also offer you the opportunity to develop new procedures for welds which have so far not been carried out in your job.

Our experience, paired with the option of quickly modifying our lasers, has often pushed the boundaries of what was previously considered feasible.

– The lowest possible thermal stress on the workpieces.

Material deformation can be almost eliminated thanks to the local application of energy.

Thanks to the extremely small heat affected zone, it is possible to carry out welds immediately next to thermally sensitive components or coatings.

In particular, very thin-walled sheets can thus be perfectly welded with no warping.

– New materials need new procedures

Laser welding often makes connections possible which, according to the literature, are not weldable. The supply of special interface additives allows for new applications and opportunities in many industries.

Thermal secondary treatment with the laser can serve to harden the material and give the material back its properties after welding with regard to flexibility.

– High process speeds

Thanks to programmable processes, very low processing times can be achieved particularly in large batch production.

“Teach in” allows for the production of serial parts without a lot of programming work.

Stepper motor controlled axes allows for repeat accuracy of better than 0.1 mm for large workpieces. For small workpieces we achieve values of better than 0.01 mm.

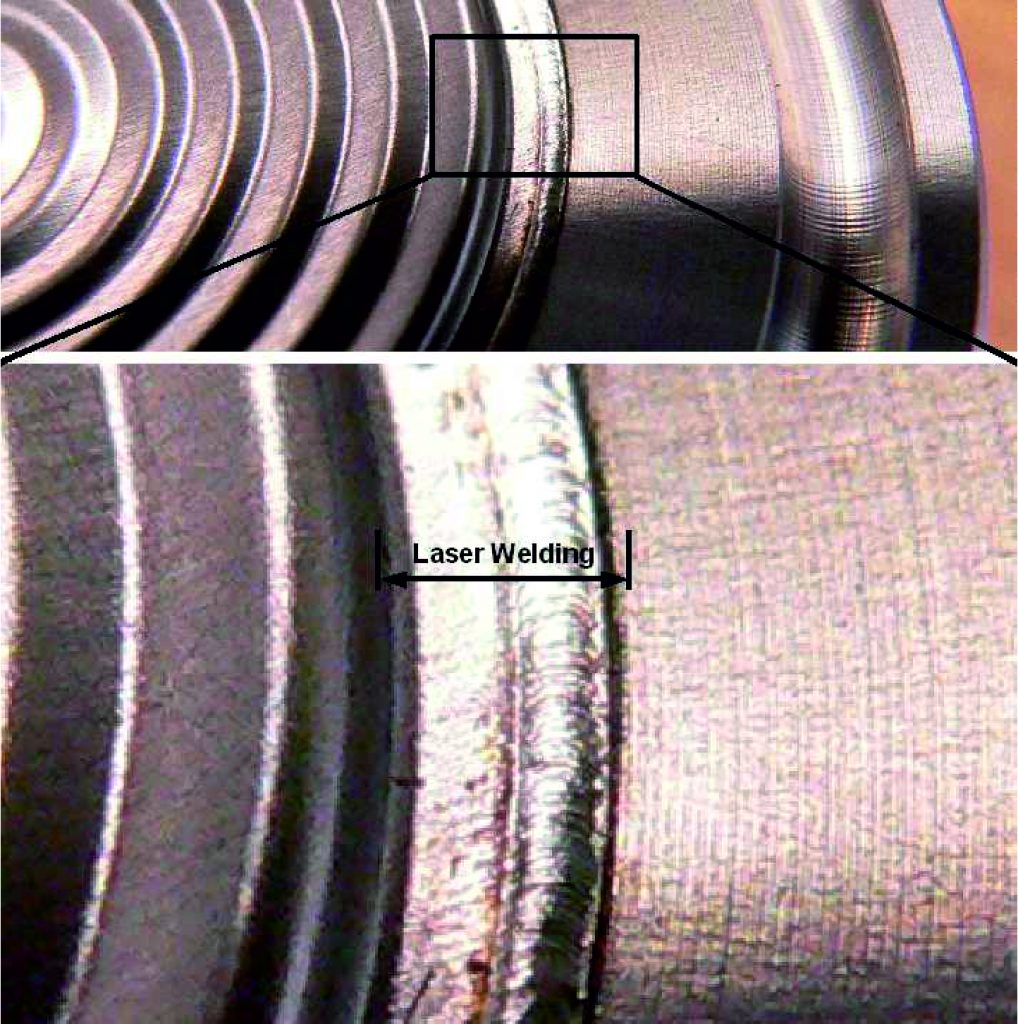

Rotation axes allow for the processing of round parts within a range of 0.1 to 150 mm.

– 20 years of experience

Our employees’ knowledge and skills from the last 20 years are available to you in our workshop.

– Outstanding aspect ratio

Our welds achieve the highest quality. High weld depth and weld width proportions offer clear cost reductions.

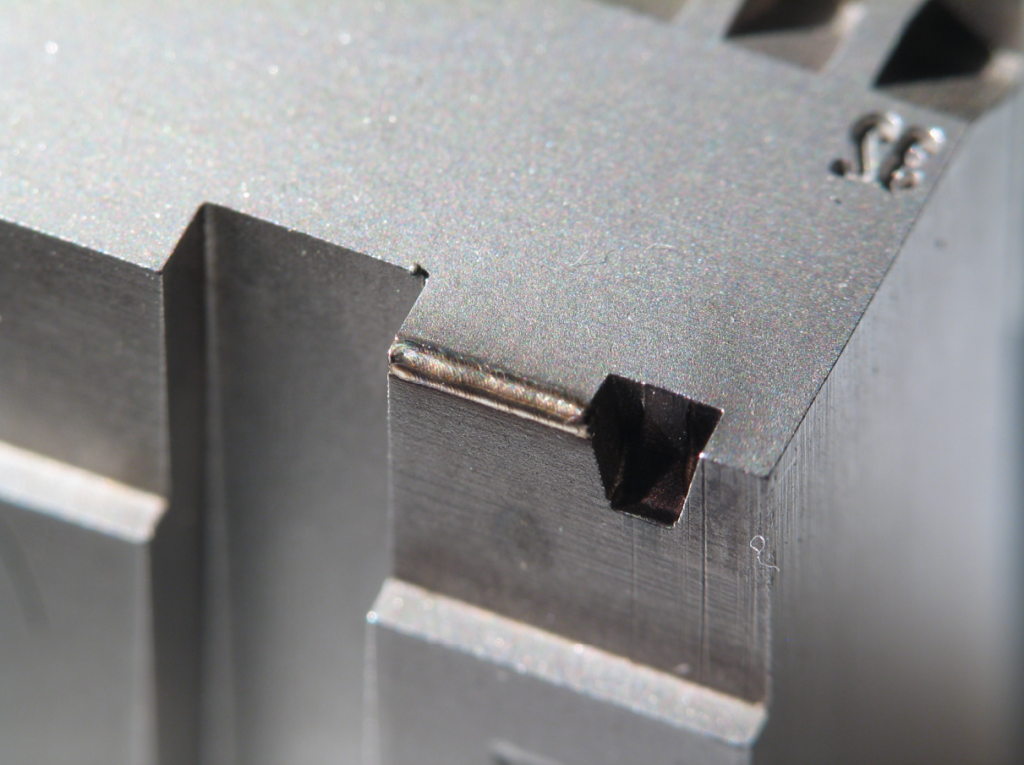

– Precision welds even at hard to reach points

Conventional welding processes quickly reach their limits, particularly in enclosures and enclosure parts. Our precision lasers allow for perfect results even at hard to reach welding points thanks to many variable lenses.

– Build-up welding and finishing

Material build-up can be achieved with the help of welding additives. We guarantee the perfect selection of the proper material here.

Computer-assisted positioning in combination with automatic wire feeding, which is synchronised with the feed rate, also allow for the homogeneous build-up of armoured surfaces or the build-up of hardened ridges.

– The smallest components up to heavyweight forms

Through the use of a wide range of laser systems, we offer you the option of being able to work on even the biggest components.

In our systems, the weld width can be within a range of 50 µm up to 2 mm.

– Just-in-time contract manufacturing

When things need to happen more quickly: we ensure the perfect timings and integrate our services into your production plan.

– Construction aids

Our in-house construction department is available to you at any time. We are happy to advise you, for example, on what changes to the construction will provide better welds. This saves time and money and often significantly improves the results.

Even the smallest welds with the highest requirements are no obstacle for our welding engineers and laser welding systems.

Whether with the use of additional wire for build-up welding or for simple joint welding: the results of laser welding are impressive.

Heavyweight moulds from the injection moulding or high pressure die casting industries can be delivered by lorry and welded in our company.

The moulds can then be used straight away after just the smallest amount of post-processing.