This unit has been developed for areas where the laser work shop needs to be prepared for any type of job. Regardless of whether thousands of small pipes need to be welded or cut today and a three ton mould delivery tomorrow, the UNIxX III will fulfils any task with the highest precision.

The many software tools provided will ensure speedy and high precision processing.

The range of 700mm in the x axis and 400mm in the y axis enable you to process big components without the necessity of them being repositioned.

Small pieces with the weight up to 300kg can be processed on the working table aforementioned in UNIXX and the working position pivoted accordingly.

The positioning and height of the working table has been designed to level with a normal office chair to allow one to sit and work ergonomically, and provides enough legroom. The sturdy table tipped at a well positioned angle ensures that there are no obstacles in your way.

When working on very big pieces, the working table can simple be swivelled to the side to allow the component to be placed under the laser by forklift. The extended range length enables you to reach the area to be repaired quickly.

The head is equipped with a bracket allowing for rotation of the laser head and enables you to weld on edges and angles.

| Technical Data | LWI V Nd:YAG 120 W |

|---|---|

| laser safety class | 4 |

| beam source | Nd:YAG, flashlamp, pulsed |

| wavelength | 1064 nm |

| max. pulse energy | 70 joule |

| max. peak power | 17 kW |

| max. average power | 120 W |

| energy adjustment mode | voltage or PWM mode |

| voltage | 160-500V |

| pulse width | 1-20 ms |

| pulse frequency | 1-20 hz |

| pulse fill | 10 - 100 % |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 200 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, water/air heat-exchanger, temperature controlled fan |

| cooling option | external cooler optional, integrated bypass-controller |

| electrical supply | 3 phases, 400V /50 hz |

| power consumption | 4 kW |

| dimensions |

| Technical Data | LWI V Nd:YAG 150 W |

|---|---|

| laser safety class | 4 |

| beam source | Nd:YAG, flashlamp, pulsed |

| wavelength | 1064 nm |

| max. pulse energy | 70 joule |

| max. peak power | 17 kW |

| max. average power | 150 W |

| energy adjustment mode | voltage or PWM mode |

| voltage | 160-500V |

| pulse width | 1-20 ms |

| pulse frequency | 1-20 hz |

| pulse fill | 10 - 100 % |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 200 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, water/air heat-exchanger, temperature controlled fan |

| cooling option | external cooler optional, integrated bypass-controller |

| electrical supply | 3 phases, 400V /50 hz |

| power consumption | 4 kW |

| dimensions |

| Technical Data | LWI V Nd:YAG 200 W |

|---|---|

| laser safety class | 4 |

| beam source | Nd:YAG, flashlamp, pulsed |

| wavelength | 1064 nm |

| max. pulse energy | 70 joule |

| max. peak power | 17 kW |

| max. average power | 200 W |

| energy adjustment mode | voltage or PWM mode |

| voltage | 200-500V |

| pulse width | 1-30 ms |

| pulse frequency | 1-30 hz |

| pulse fill | 10 - 100 % |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 200 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, water/water heat-exchanger, external cooling required |

| cooling option | external cooling required |

| electrical supply | 3 phases, 400V /50 hz |

| power consumption | 4 kW |

| dimensions |

| Technical Data | LWI V Nd:YAG 300 W |

|---|---|

| laser safety class | 4 |

| beam source | Nd:YAG, flashlamp, pulsed |

| wavelength | 1064 nm |

| max. pulse energy | 70 joule |

| max. peak power | 17 kW |

| max. average power | 300 W |

| energy adjustment mode | voltage or PWM mode |

| voltage | 200-700V |

| pulse width | 1-30 ms |

| pulse frequency | 1-30 hz |

| pulse fill | 10 - 100 % |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 200 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, water/water heat-exchanger, external cooling required |

| cooling option | external cooling required |

| electrical supply | 3 phases, 400V /50 hz |

| power consumption | 9 kW |

| dimensions |

| Technical Data | LWI V FSS 150 W |

|---|---|

| laser safety class | 4 |

| beam source | FSS FullSolidState Fibrelaser, Diodes |

| wavelength | 1070 nm |

| max. pulse energy | 15 Joule |

| max. peak power | 1,5 kW |

| max. average power | 150 W |

| energy adjustment mode | current |

| voltage | 10 - 100 % |

| pulse width | 0,1 - 50 ms /cw |

| pulse frequency | 1-100 hz |

| pulse fill | - |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 100 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, temperature controlled fan |

| cooling option | - |

| electrical supply | 1-phasig, 90-250V, 50/60 hz |

| power consumption | 800 W |

| dimensions |

| Technical Data | LWI V FSS 300 W |

|---|---|

| laser safety class | 4 |

| beam source | FSS FullSolidState Fibrelaser, Diodes |

| wavelength | 1070 nm |

| max. pulse energy | 30 Joule |

| max. peak power | 3 kW |

| max. average power | 300 W |

| energy adjustment mode | current |

| voltage | 10 - 100 % |

| pulse width | 0,1 - 50 ms /cw |

| pulse frequency | 1-100 hz |

| pulse fill | - |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 100 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, temperature controlled fan |

| cooling option | - |

| electrical supply | 1 Phase , 90-250V, 50/60 hz |

| power consumption | 1,2 kW |

| dimensions |

| Technical Data | LWI V FSS 450 W |

|---|---|

| laser safety class | 4 |

| beam source | FSS FullSolidState Fibrelaser, Diodes |

| wavelength | 1070 nm |

| max. pulse energy | 45 Joule |

| max. peak power | 4,5 kW |

| max. average power | 450 W |

| energy adjustment mode | current |

| voltage | 10 - 100 % |

| pulse width | 0,1 - 50 ms /cw |

| pulse frequency | 1-100 hz |

| pulse fill | - |

| PWM mode | - |

| focal length | 190 mm |

| beam diameter | 100 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, temperature controlled fan |

| cooling option | - |

| electrical supply | 1 Phase , 90-250V, 50/60 hz |

| power consumption | 2,5 kW |

| dimensions |

| Technical Data | LWI V FSS 600W |

|---|---|

| laser safety class | 4 |

| beam source | FSS FullSolidState Fibrelaser, Diodes |

| wavelength | 1070 nm |

| max. pulse energy | 60 Joule |

| max. peak power | 6 kW |

| max. average power | 600 W |

| energy adjustment mode | current |

| voltage | 10 - 100 % |

| pulse width | 0,1 - 50 ms /cw |

| pulse frequency | 1-100 hz |

| pulse fill | |

| PWM mode | |

| focal length | 190 mm (120 mm, 300 mm) |

| beam diameter | 100 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, temperature controlled fan |

| cooling option | |

| electrical supply | 1 Phase , 90-250V, 50/60 hz |

| power consumption | 2,5 kW |

| dimensions |

Precisely controls axis movements. This extends manual welding by its sophisticated automatic and programable functions. Touchscreen and Joystick terminals directly in your workspace provide a unique, simple control concept. Thanks to the completely integrated hardware, a separate computer is not needed.

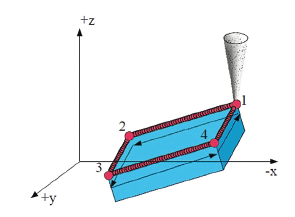

Enables the handling of complicated geometries in four axis without complex programming. A small number of support points are hit once on the contour of the work piece in advance. The user can subsequently move the programmed welding line forward and backward using the joystick and can also shift its position by offsetting the start point.

Enables the handling of complicated geometries in four axis without complex programming. A small number of support points are hit once on the contour of the work piece in advance. The user can subsequently move the programmed welding line forward and backward using the joystick and can also shift its position by offsetting the start point.

You can process circular type contours by using the PCD function with the XY axis. The circular path is precisely defined through the teaching of only three support points. You do not need to know the center or the diameter; the position on the work piece is optional. You can move along the programmed course either forward or backward by using the joystick.

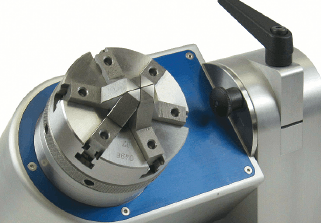

Specially developed turning units increase the user value of your workstation. They incorporate all functions of CAN-Step control, available at the touch of a button, including pulse synchronization and „Teach in“ programming. Additional features: • Swivel-mounted • Free implementation up to Ø40 mm • different chuck types, chucking range up to Ø 160 mm.

The useful high load capacity work table can be revolved under the laser head. The plain-milled slot profile worktop can be rotated and is locked. Supports and worktops provide free lead through. This allows you to weld long work pieces smoothly.