– Two Z-axes for an ergonomic sitting position

– Ergonomic workspace with covered guideways for processing long workpieces

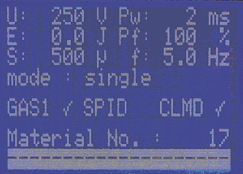

– All functions can be controlled from an external terminal on the worktop

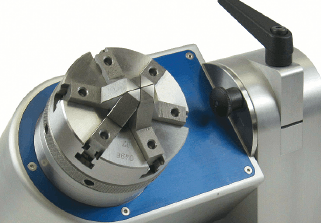

– Optional extension for pulse-synchronised circumferential welding

– Available for all Vision Lasertechnik GmbH beam sources

For applications that require more working space or power than our manual laser welding workstations have to offer, our ERGO workstation is the perfect solution.

Select a laser welding system of the LWI V series and configure your laser workstation according to your specific requirements.

The two Z-axes enable an ergonomic posture during work and can be individually adjusted to the body height of the user.

With a large selection of optional accessories, the workstation can be precisely configured according to your budget and application.

With our stand-alone controller and one of our rotary units, this is the favoured and most cost-efficient welding solution for rotationally symmetrical workpieces.

Thanks to special recesses in the ergonomic tabletop, also very long workpieces can be welded from various angles.

| Technical Data | LWI V Nd:YAG 120 W |

|---|---|

| laser safety class | 4 |

| beam source | Nd:YAG, flashlamp, pulsed |

| wavelength | 1064 nm |

| max. pulse energy | 70 joule |

| max. peak power | 17 kW |

| max. average power | 120 W |

| energy adjustment mode | voltage or PWM mode |

| voltage | 160-500V |

| pulse width | 1-20 ms |

| pulse frequency | 1-20 hz |

| pulse fill | 10 - 100 % |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 200 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, water/air heat-exchanger, temperature controlled fan |

| cooling option | external cooler optional, integrated bypass-controller |

| electrical supply | 3 phases, 400V /50 hz |

| power consumption | 4 kW |

| dimensions | 1199mm x 700mm x 948mm |

| Technical Data | LWI V Nd:YAG 150 W |

|---|---|

| laser safety class | 4 |

| beam source | Nd:YAG, flashlamp, pulsed |

| wavelength | 1064 nm |

| max. pulse energy | 70 joule |

| max. peak power | 17 kW |

| max. average power | 150 W |

| energy adjustment mode | voltage or PWM mode |

| voltage | 160-500V |

| pulse width | 1-20 ms |

| pulse frequency | 1-20 hz |

| pulse fill | 10 - 100 % |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 200 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, water/air heat-exchanger, temperature controlled fan |

| cooling option | external cooler optional, integrated bypass-controller |

| electrical supply | 3 phases, 400V /50 hz |

| power consumption | 4 kW |

| dimensions | 1199mm x 700mm x 948mm |

| Technical Data | LWI V FSS 150 W |

|---|---|

| laser safety class | 4 |

| beam source | FSS FullSolidState Fibrelaser, Diodes |

| wavelength | 1070 nm |

| max. pulse energy | 15 Joule |

| max. peak power | 1,5 kW |

| max. average power | 150 W |

| energy adjustment mode | current |

| voltage | 10 - 100 % |

| pulse width | 0,1 - 50 ms /cw |

| pulse frequency | 1-100 hz |

| pulse fill | - |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 100 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, temperature controlled fan |

| cooling option | - |

| electrical supply | 1-phasig, 90-250V, 50/60 hz |

| power consumption | 800 W |

| dimensions | 1199mm x 700mm x 948mm |

| Technical Data | LWI V FSS 300 W |

|---|---|

| laser safety class | 4 |

| beam source | FSS FullSolidState Fibrelaser, Diodes |

| wavelength | 1070 nm |

| max. pulse energy | 30 Joule |

| max. peak power | 3 kW |

| max. average power | 300 W |

| energy adjustment mode | current |

| voltage | 10 - 100 % |

| pulse width | 0,1 - 50 ms /cw |

| pulse frequency | 1-100 hz |

| pulse fill | - |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 100 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, temperature controlled fan |

| cooling option | - |

| electrical supply | 1 Phase , 90-250V, 50/60 hz |

| power consumption | 1,2 kW |

| dimensions | 1199mm x 700mm x 948mm |

| Technical Data | LWI V FSS 450 W |

|---|---|

| laser safety class | 4 |

| beam source | FSS FullSolidState Fibrelaser, Diodes |

| wavelength | 1070 nm |

| max. pulse energy | 45 Joule |

| max. peak power | 4,5 kW |

| max. average power | 450 W |

| energy adjustment mode | current |

| voltage | 10 - 100 % |

| pulse width | 0,1 - 50 ms /cw |

| pulse frequency | 1-100 hz |

| pulse fill | - |

| PWM mode | - |

| focal length | 190 mm |

| beam diameter | 100 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, temperature controlled fan |

| cooling option | - |

| electrical supply | 1 Phase , 90-250V, 50/60 hz |

| power consumption | 2,5 kW |

| dimensions | 1199mm x 700mm x 948mm |

Specially developed turning units increase the user value of your workstation. They incorporate all functions of CAN-Step control, available at the touch of a button, including pulse synchronization and „Teach in“ programming. Additional features: • Swivel-mounted • Free implementation up to Ø40 mm • different chuck types, chucking range up to Ø 160 mm.

The ergonomically arranged display and terminal located closley behind the microscope give you a direct view of all the important operating parameters. The integrated energy measuring system indicates the emitted energy after every laser pulse and therefore enables the monitoring of the welding process as well as the precise adjustment of the pulse energy.

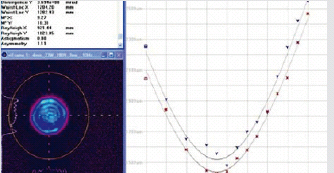

The innovative Beam Tuning Set combined with booster technology guarantees a stable output even with very low pulse energies. This is particulary beneficial when it comes to welding extremely small parts. The spot size can be reduced to 50 μm. This feature is available as either a fixed installation or a manually connectable option.

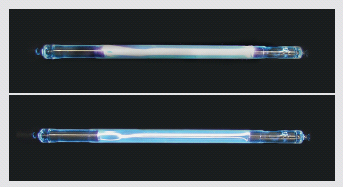

Booster technology for long lamp lifespan and heightened pulse stability The booster enables you to further raise the „pulse to pulse stability“ and to lengthen the lifespan of the flash lamp. Shortly before the shoot, the simmer power is automatically increased, thus stabilizing the plasma in the lamp and increasing the electrode temperature. This leads to a substanitially more stable energy output of the laser, especially with low energy.

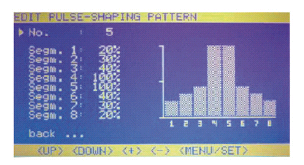

Free pulse shaping enables the setting and saving of all possible variations in the pulse process. Materials with different thermal coefficients of expansion thus show a clearly better welding behaviour - your laser´s area of application thus expands.

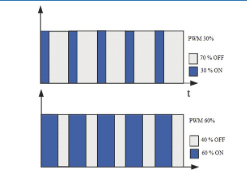

In the lower power range, which depends upon high stability, traditional lasers are inclinined toward a low „pulse to pulse stability“ and thus to a non-uniform welding result. The Pulse Width Modulation (PWM) gives a vastly more fine and stable coordination, as the internal energy supply here works in the area of the optimal output.

In order to eliminate the oxidation of the welded joint directly after it has been welded, the times during which the shielding gas ist still conducted on the welded joint following the welding can be individually set.